SA588 SA387 Alloy Steel Phaj

Kev cuam tshuam ntawm cov ntsiab lus alloy ntawm cov txheej txheem ntawm cov hlau

1. Kev cuam tshuam ntawm cov ntsiab lus alloy ntawm steel casting kev ua tau zoo

Qhov qis dua qhov kub ntawm cov khoom thiab cov kua theem kab thiab qhov nqaim ntawm qhov chaw crystallization kub yog, qhov zoo dua qhov kev ua haujlwm casting yog.Kev cuam tshuam ntawm cov ntsiab lus alloy ntawm qhov kev ua tau zoo yog nyob ntawm lawv qhov cuam tshuam ntawm Fe-Fe3C daim duab theem.Tsis tas li ntawd, ntau lub ntsiab lus, xws li Cr, Mo, V, Ti, Al, tsim high melting point carbide los yog oxide hais nyob rau hauv steel, uas ua rau kom lub viscosity ntawm hlau, txo lub fluidity, thiab deteriorate lub casting kev ua tau zoo.

2. Kev cuam tshuam ntawm cov ntsiab lus alloy ntawm yas machining hlau

Kev ua cov yas yog muab faib ua kev ua cua sov thiab ua haujlwm txias.Alloy cov ntsiab lus rau hauv cov khoom sib tov, los yog tsim cov carbide (xws li Cr, Mo, W, thiab lwm yam), txhim kho cov thermal deformation tsis kam ntawm hlau thiab qhov tseem ceeb poob ntawm thermoplasticity thiab yooj yim rau forge thiab tawg.Cov txheej txheem thermal ua kev ua tau zoo ntawm cov hlau alloy dav dav yog qhov phem dua li cov hlau carbon.

3. Cov nyhuv ntawm cov ntsiab lus alloy ntawm cov khoom siv vuam ntawm cov hlau

Cov ntsiab lus alloy tag nrho txhim kho cov quenability ntawm cov hlau, txhawb kev tsim cov nqaij ntshiv (martensite), thiab ua rau cov vuam ua haujlwm tsis zoo.Txawm li cas los xij, cov hlau muaj qhov me me ntawm Ti thiab V, uas tuaj yeem txhim kho qhov kev ua tau zoo ntawm cov hlau.

4. Kev cuam tshuam ntawm cov ntsiab lus ntawm cov hlau txiav kev ua tau zoo ntawm kev ua tau zoo yog cuam tshuam nrog cov hardness ntawm cov hlau, steel yog tsim rau kev txiav hardness ntau ntawm 170 HB ~ 230 HB.Qhov kev ua tau zoo ntawm cov hlau alloy dav dav yog phem dua li cov hlau carbon.Txawm li cas los xij, qhov tsim nyog ntxiv ntawm S, P, Pb thiab lwm yam tuaj yeem txhim kho kev ua haujlwm ntawm cov hlau.

5. Kev cuam tshuam ntawm cov ntsiab lus alloy ntawm kev ua haujlwm ntawm cov txheej txheem kev kho cua sov ntawm cov hlau

Kev ua haujlwm ntawm cov txheej txheem kev kho cua sov qhia txog qhov nyuaj ntawm kev kho cua sov steel thiab qhov nyiam ntawm kev kho cua sov.Nws feem ntau suav nrog quenability, overheating rhiab heev, tempering embrittlement thiab oxidative decarbonization.Alloy steel muaj siab quenability, thiab ib tug kuj qeeb txias txoj kev yuav siv tau thaum quenching, uas yuav txo tau lub deformation thiab cracking nyiam ntawm lub workpiece.Ntxiv manganese thiab silicon yuav ua rau muaj kev kub ntxhov ntawm cov hlau.

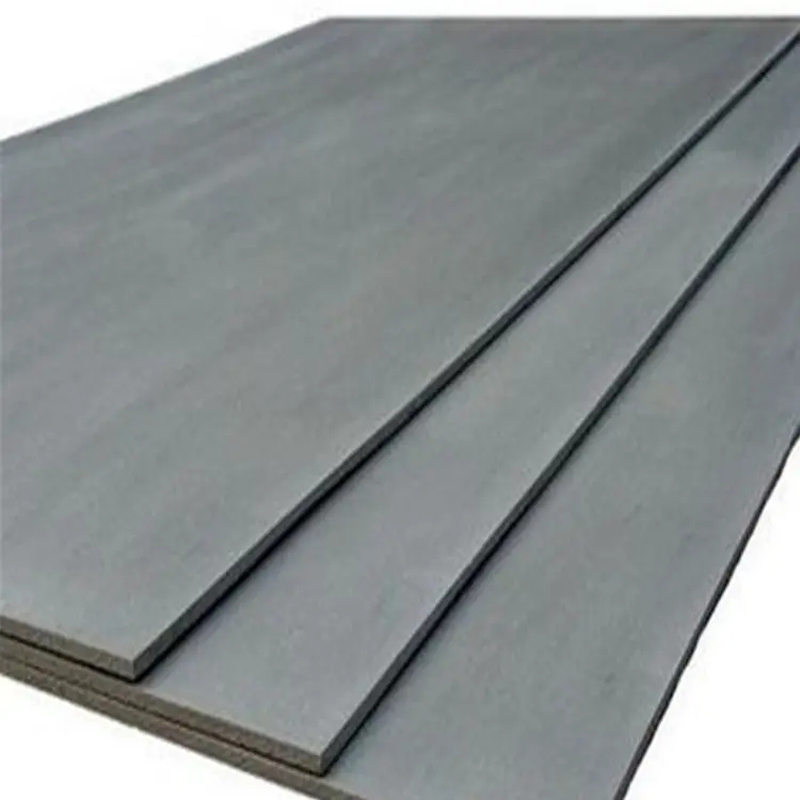

Product Detail

| Steel Qib: | 15CrMo, 12CrMoV, EN: S235JR, S275JR, S355JR, S420NL, S460NL, S500Q, S550Q, S620Q, S690Q ASTM: Qib B, Qib C, Qib D, A36, Qib 36, Qib 40, Qib 42, Qib 50, Qib 55, Qib 60, Qib 65, Qib 70, Qib JIS: SPHC, SS400, SPFC, SPHD, SPHE |

| Txheem: | DIN EN 10083, ASME SA516, ASTM A203M, ASME SA588, ASME SA387, SAE1045 JIS G4051, AISI, BS |

| Thickness: | 1.0-300 hli |

| Dav: | 100-4500mm, los yog raws li tus neeg thov tshwj xeeb |

| Ntev: | 1-20meters, los yog raws li tus neeg thov tshwj xeeb |

| Pob: | Export Standard Pob |

| Daim ntawv thov: | 1.Machinery, Siab hlab ntsha industries. 2.Shipbuilding, Engineering tsim. 3.Automobile, choj, vaj tse. 4.Mechanical manufacturing, Pavement slab, ect. |

| Mill MTC: | Muab khoom ua ntej khoom xa tuaj |

| Kev tshuaj xyuas: | Kev tshuaj xyuas thib peb tuaj yeem lees txais, SGS, BV, TUV |

| Mount Chaw nres nkoj: | Txhua qhov chaw nres nkoj hauv Suav teb |

| Trade Term: | FOB, CIF, CFR, EXW, thiab lwm yam. |

| Nqe Sijhawm: | TT lossis LC thaum pom |

| Peb Cov Kev Pabcuam: | Peb tuaj yeem txiav thiab khoov steel phaj raws li cov neeg siv khoom xav tau lossis kos duab, ntim raws li cov neeg siv khoom thov |

Factory Show