A106B A210A1 A210C / Carbon Steel Seamless yeeb nkab

Kev soj ntsuam zoo ntawm seamless steel yeeb nkab

1. Tshuaj muaj pes tsawg leeg tsom xam: chemical tsom xam, ntsuas ntsuas (infrared CS ntsuas, ncaj qha nyeem spectrometer, zcP, thiab lwm yam).

① Infrared CS ntsuas: tsom xam ntawm ferroalloy, steelmaking raw khoom, C, S ntsiab nyob rau hauv steel.

② Direct nyeem ntawv spectrometer: C, Si, Mn, P, S, Cr, Mo, Ni, Cn, A1, W, V, Ti, B, Nb, As, Sn, Sb, Pb, Bi hauv cov qauv thaiv

③ N- -0 ntsuas: ntsuas roj cov ntsiab lus N thiab O.

2. Kev soj ntsuam zoo ntawm cov yeeb nkab steel: 100%

① Kev tshuaj xyuas qhov muag pom: teeb pom kev zoo, qauv, kev paub, kev txheeb xyuas, kev sib hloov steel yeeb nkab.

② NDT kev tshuaj xyuas:

A. Ultrasonic nrhiav kom tau UT:

B. ET: (electromagnetic induction)

C. MT thiab kev kuaj pom dej:

Magnetic flaw detection, haum rau kev tshawb nrhiav ntawm qhov chaw thiab ze-nto qhov chaw ntawm cov ntaub ntawv ferromagnetic.

D. Electromagnetic ultrasonic tsis pom kev:

Tsis xav tau kev sib txuas nruab nrab, uas tuaj yeem siv rau qhov kub thiab txias, kev ntxhib thiab qhuav steel yeeb nkab nto qhov tsis zoo.

E. Liquid nkag mus kuaj:

Fluorescence, xim, thiab kuaj xyuas cov yeeb nkab steel defects.

3. Kev tshuaj xyuas lub cev thiab tshuaj lom neeg ntawm cov yeeb nkab steel:

① Tensile xeem: ntsuas qhov kev ntxhov siab thiab deformation, txiav txim siab lub zog ntawm cov khoom (YS, TS) thiab cov yas ntsuas (A, Z)

Longitudinal, transverse seem, arc, ncig (¢ 10, ¢ 12.5)

Me txoj kab uas hla, nyias phab ntsa, txoj kab uas hla loj, tuab phab ntsa calibration nrug.

② Impact test: CVN, notch C, V, ua haujlwm J tus nqi J / cm2

Qauv qauv 101055 (mm) Tsis yog-tus qauv qauv 55 5 (mm)

③ Hardness test: Brinell hardness HB, Rockell hardness HRC, Vickers hardness HV, thiab lwm yam

④ Hydraulic xeem: ntsuas siab, lub sijhawm ruaj khov, p = 2S δ / D

4. Txheej txheem kev soj ntsuam ntawm cov yeeb nkab steel:

① Kev sim tiaj tus: puag ncig qauv C-zoo li tus qauv (S / D & gt; 0.15) H = (1 + 2) S / (+ S / D)

L = 40 ~ 100mm ib chav tsev ntev deformation coefficient = 0.07 ~ 0.08

② Pull test: L = 15mm tsis muaj qhov tawg yog tsim nyog

③ Expansion thiab curling xeem: lub sab saum toj taper yog 30 °, 40 ° thiab 60 °

④ Bending test: tuaj yeem hloov qhov kev sim flattening (rau txoj kab uas hla loj).

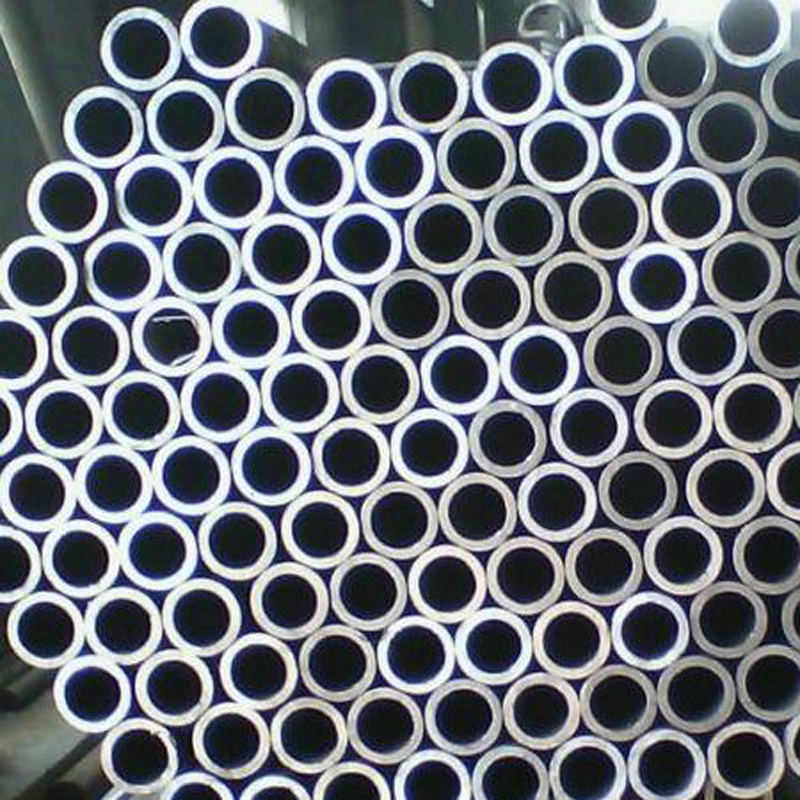

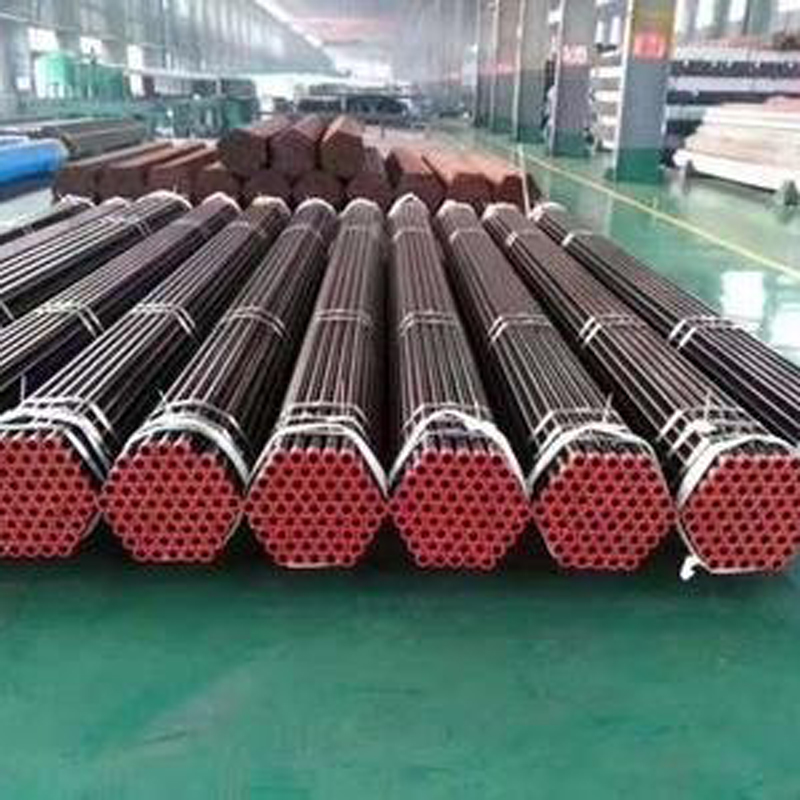

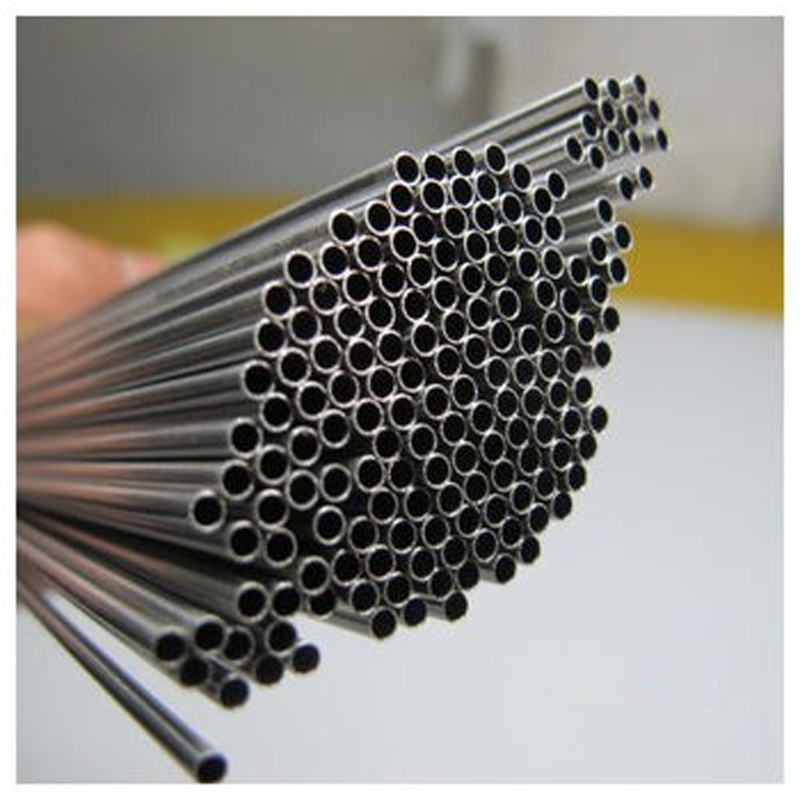

Product Detail

| Steel Qib: | 106B,210A1,210C,P9,P11,T1,T11,T2,T5,T12,T22,T23,T91,T92,P235GH,13CrMo4-5,15Mo3,10CrMo9-10, ST35.8, ST45.8, STB340, STBA 12-2, API5L, 5CT |

| Txheem: | ASTM SA / A53 / 513 / 106 / 209 / 210 / 213 / 335 / 178 / 179 / 519 ASME / ASTM SA / A213, A312, A269, A778, A789, DIN 17456, DIN17457, DIN 17459, DIN17175, EN10216, BS3605, BS3059 |

| Specification: | Sab nraud 10 ~ 508mm |

| Wt: | 1.0-30mm, los yog raws li tus neeg thov tshwj xeeb |

| Ntev: | 2-20meters, los yog raws li tus neeg thov tshwj xeeb |

| Pob: | Export Standard Pob |

| Hom tube: | Boiler tube, precision raj, mechanical tubing, lub tog raj kheej raj, kab kav, thiab lwm yam |

| Mill MTC: | Muab khoom ua ntej khoom xa tuaj |

| Kev tshuaj xyuas: | Kev tshuaj xyuas thib peb tuaj yeem lees txais, SGS, BV, TUV |

| Mount chaw nres nkoj: | Txhua qhov chaw nres nkoj hauv Suav teb |

| Trade Term: | FOB, CIF, CFR, EXW, thiab lwm yam. |

| Nqe Sijhawm: | TT lossis LC thaum pom |

| Peb cov kev pabcuam: | Peb tuaj yeem kho raws li cov neeg siv khoom xav tau lossis kos duab, ntim raws li cov neeg siv khoom thov |

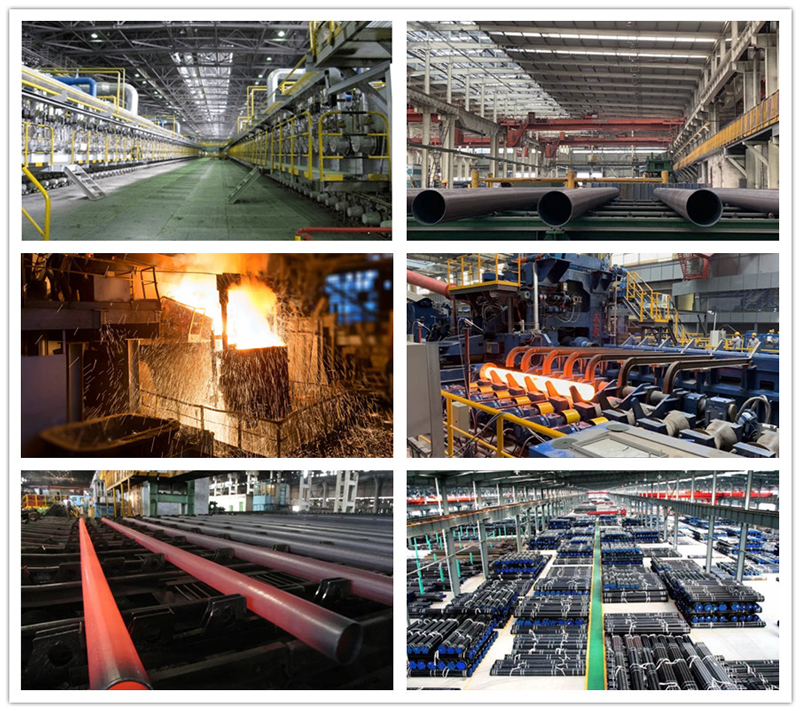

Factory Show